Are your needs growing? Our measuring instruments grow with you!

Ergonomics enable stress-free, effective working

innovation and fair pricing –

today and in the future.

Quality assurance is far more than the use of suitable measuring equipment.

It is the optimal combination of reliable measuring instruments, ergonomic operation and the use of functional accessories.

Increasing demands in terms of flexibility, cost pressure and short set-up times call for accessories suitable for universal use and highly efficient in operation. Professional auxiliary systems offer you clear differentiation from the competition, for example in the form of flexibility, safety, cost efficiency and high-speed responsiveness.

We are a globally operating manufacturer of measuring instruments, a solutions provider and project service provider for small to complex, needs-optimised auxiliary systems.

Take advantage of our extensive know-how and forward-looking products. Measuring instrument accessories by T&S stand for tailor-made, ergonomic, innovative concepts – from simple workpiece support to complex, intelligent measuring equipment.

In developing our products, our focus was always on you as a discerning user and measurement engineer. The result is a comprehensive range of accessories and auxiliary devices to resolve your measurement tasks. Your qualified suggestions and optimisation proposals motivate us to continually develop and improve our systems.

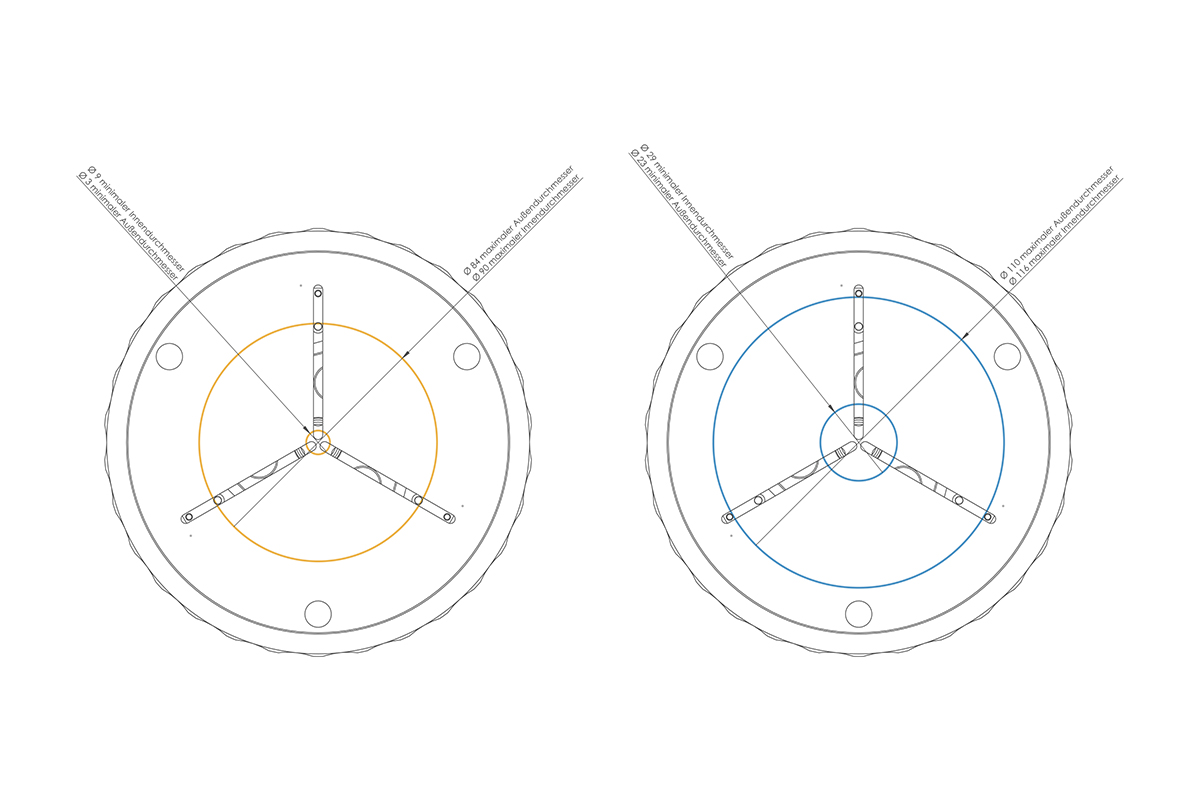

Our universal, patented system for external and internal centring of round test specimens.

“The guide of the universal centring system corresponds to a non-linear curve. As a result, we achieve an outwardly increasing centring force. Larger, also usually heavier, test specimens are centred with a greater force than small, light workpieces.” The centring elements are secured by means of threads and can be adapted for specific tasks. An adapter plate for fastening popular form measuring devices to rotary machine tables is included.

UZ-160 for external and internal centring of round specimens up to a diameter of 145 mm

UZ-240 for external and internal centring of round specimens up to a diameter of 230 mm with integrated magnetic strips (optional)

UZ-160 scope of application

UZ-240 scope of application

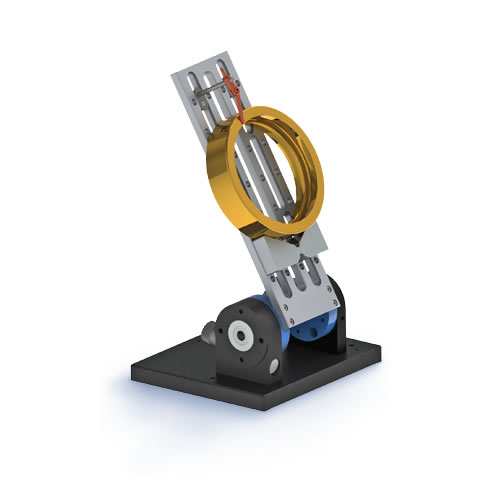

Tilting and centring table for levelling and configuring the X/Y axes

It is operated manually using fine-thread spindles. The position and incline can be adjusted for each axis. Alternatively, we can also include our KZT with a UZ/AZ adjustable tilting and centring table.

KZT-160 Tilting and centring table // KZT-160 with adjustable UZ-160

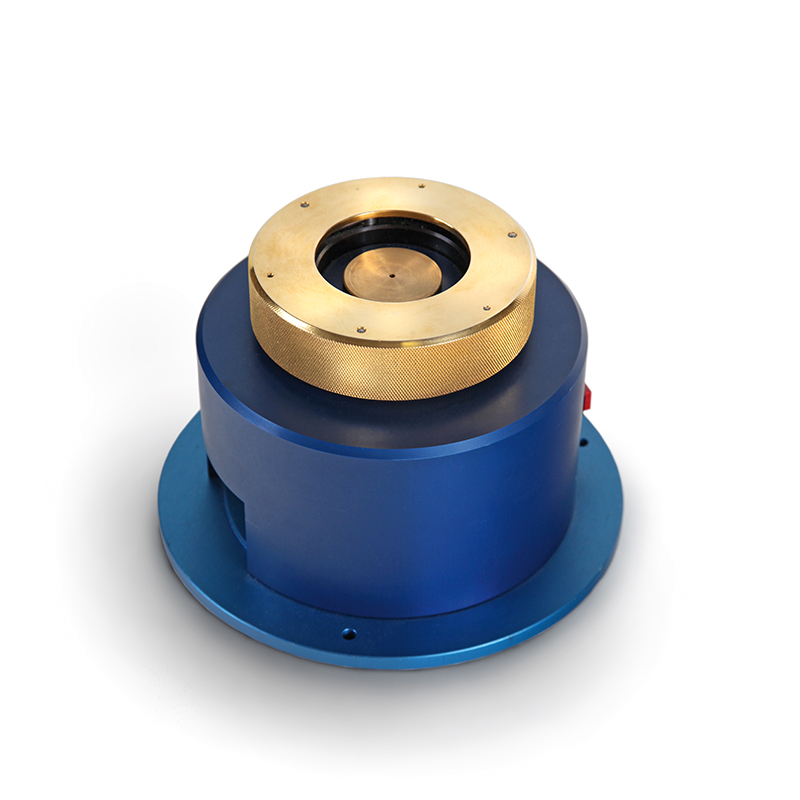

Centring device designed as a centring and positioning aid for installation on form measuring devices.

By rotating the outer ring, three arms are moved centrically to the centre of the holder. The arms are kept under tension by means of a spiral spring and thereby centre the test specimen. Due to the good mechanical performance, post-centring is generally unnecessary or is reduced to a minimum. The low centring forces also permit the clamping of thin-walled parts without mechanical deformation.

Customised specifications available upon request. For example:

- Height-adjustable centring arms

- Centring arms with locating holes for clamping discs, etc.

- Workpiece support plate with magnetic strips.

AZ-1

Angle-adjustable, centrical clamping vice with radial rotary holder.

Due to centrical clamping, the measuring axis of symmetrical workpieces remains in the measuring axis at all times. Constant repositioning of the workpiece holder for different test specimen dimensions is therefore no longer necessary.

Our ZS vice is available as an additional extra with radial rotary unit and angle adjustment via worm drive. The movement axes can be clamped in the respective position.

ZSR-60 jaw width 60 mm

Battery-powered vacuum centring and clamping system with integrated, low-vibration special vacuum pump for rotary table systems.

For test specimens which cannot be clamped using the usual methods, small or flat parts, balls or bolts that have to be inspected along their entire length, asymmetric parts, etc.

VZ-1 with AZ-1 centring system // VZ-1 with AZ-1 centring system, example of use

Angle-adjustable universal clamps for the positioning of bearing rings on contour measurement systems.

The central groove allows the measuring probe to pass through to behind the workpiece. The tilting movement of the workpiece is facilitated by means of a worm drive. For the support, a movable prism and support bolts are included. To prevent the tilting of the test specimen, a movable, spring-loaded retaining element has been integrated into the device.

Resilient bearing balls for determining the measurement of the rear face and magnetic inserts for securing the placed part are available as additional extras.

WSE-300: Angle-adjustable universal clamps for the positioning of bearing rings

Teileauflage auf parallel angeordneten Wellen als Alternative zu Prismen.

Die Vorteile dieser Ausführung sind das geringe Gewicht, der große Anwendungsbereich (Ø 25-350mm), die leichte Zugänglichkeit von oben und unten und das leichte Handling. Optional können wir verschiebbare Anschläge und Elemente zur Teilefixierung liefern.

VZ-1 mit AZ-1 Zentriersystem // VZ-1 mit AZ-1 Zentriersystem – Anwendungsbeispiel

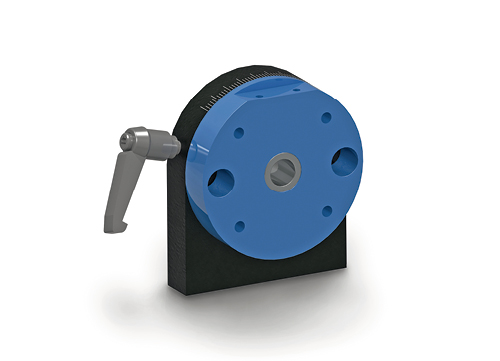

SG series:

Radial rotary unit for angle adjustment with ergonomically slanted drive wheel. Reading of the swivel angle is carried out via the laser-etched scale. The rotary axis can be fixed in the set position via a clamping lever.

SG-1

SG-1 Vario B

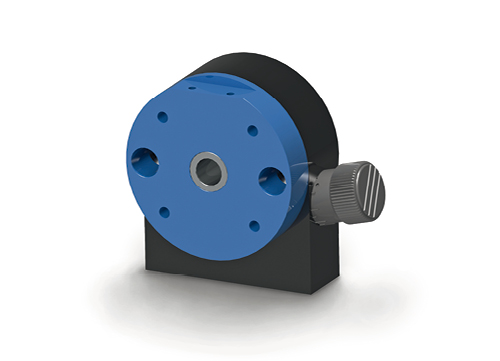

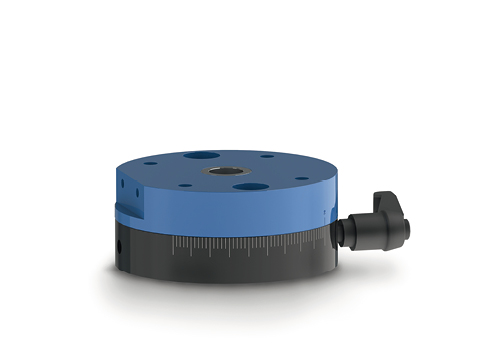

DP series

Radial rotary unit for angle adjustment with angle scale. The rotary axis can be fixed in the set position via a clamping lever.

DP-1

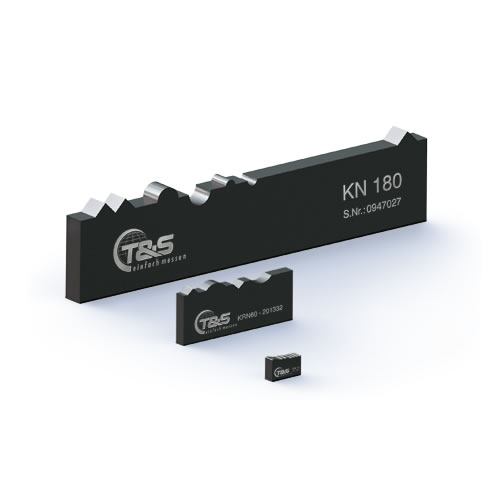

Each measuring device is only as good as its reference. To monitor the precision and testing of contour measuring instruments, for instance in accordance with VDI/VDE 2629, we offer a wide range of contour and roughness standards. Depending on the model, our standards are manufactured from hardened and aged gauge steel or hard metal.

As an additional extra, our standards are also available with a nearly adamantine, extremely wear-resistant surface coating. Stable mounting blocks or mounts with precision tilt axes are available for safely supporting our standards

KN-180

- New: Test station with measuring elements and support prisms that automatically adjust to the respective test specimen type

- New: Dynamic rotor test of angular displacement from collector to skew-slotted laminated core

- Robust mechanics

- Ergonomic operation

- Easily adjustable elements

- Unrivalled short resetting time

- Modular design

- Easy adaptation to advanced measurement tasks

- Integration of external test systems, for example for roughness testing

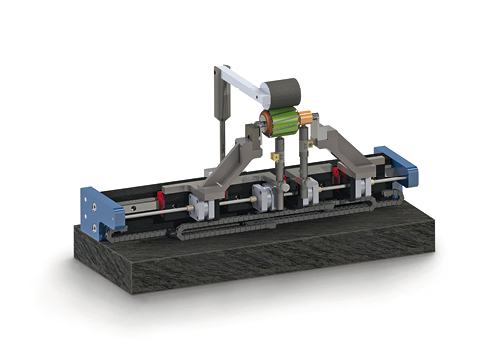

IKP-500 commutator testing system with automatic positioning of the measuring elements

- Dynamic T&S USB interface

- Dynamic data recording of inductive displacement transducer signals with up to 4,000 MW/s simultaneously on up to eight channels

- Dynamic data recording of analogue voltages of up to 50,000 MW/s simultaneously on up to eight channels

- Integration of almost all common displacement transducers and interfaces

- Adaptable tactile and non-contact laser sensors

- Control of various motor controllers

- Communication with PLC of production lines

- Data exchange with higher-level CAQ systems

- Variable I/O for integration of remote control switches

- Flexible, ergonomic operation

- Integration of almost all popular calculation algorithms of the commutator geometry

- Data transfer interface and integration of external test systems, for example roughness testing

- Numerical and graphical representation of results

- Graphical display of tolerance violations

- Linear, polar or combined representation

- SPC analysis

- CAQ data export

- Results view as table

- User management

- Status display of control inputs and outputs

- Communication with PLC of Production lines

- Typical cycle times including evaluation < 2 s

- Evaluation of parameters

- Bar-to-bar difference

- Delta bar

- Bar-to-bar difference on encapsulated commutator

- Segment form deviation

- Commutator concentricity

- Commutator roundness

- Commutator diameter

- Concentricity to shaft/worm

- Concentricity on encapsulated commutator

- Shaft roundness

- Shaft diameter

- Angular offset to laminated disc pack

- Pack concentricity

- Concentricity on encapsulated packs

- Pack diameter

- Height of welding hook

Do your needs require an individual solution? No problem!

From auxiliary devices to automatic testing machines with special software, we find the right solution with the help of our special measurement technology.

Example of a workpiece mount with ZS-60 and Y-positioning unit