Concept:

Focussing on the essentials.

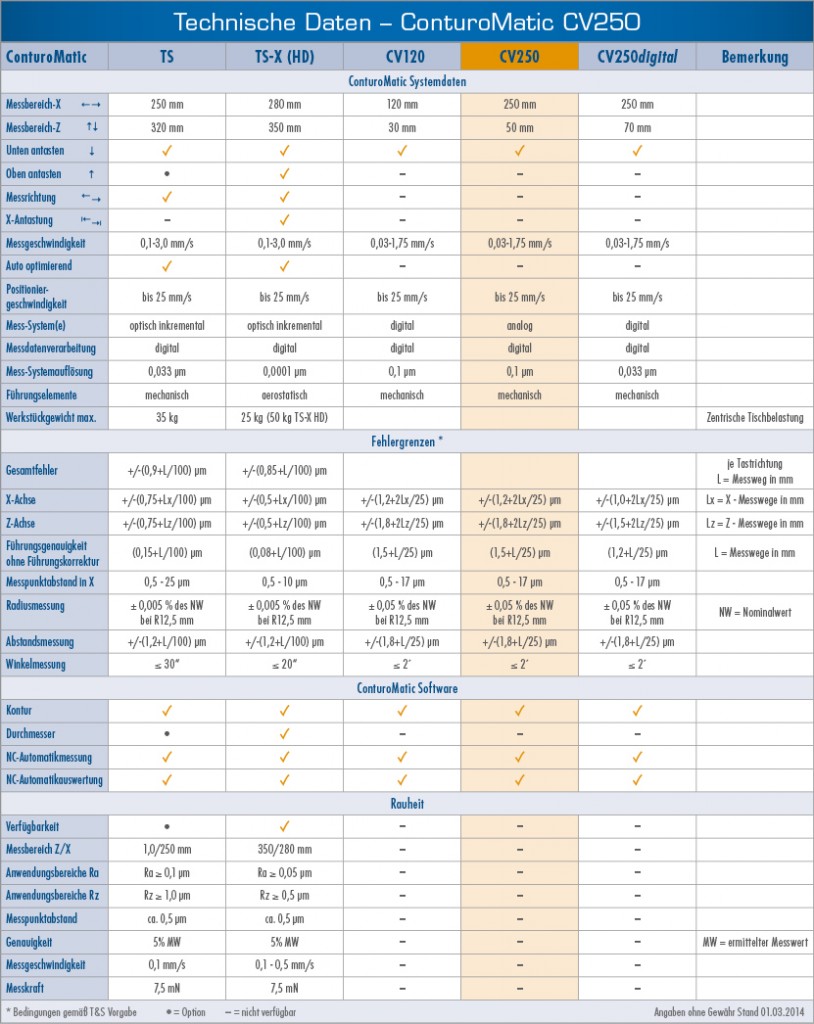

The ConturoMatic CV series are classic contour measuring devices that boast intelligent functions and useful automation. They offer everything that a high-performance and reliable contour measuring system needs.

Originally designed to monitor industrial manufacturing processes, our CV series also does a great job in the measuring lab thanks to its durable mechanics and high-performance software. Workpieces can be measured automatically in the entire measuring area. The calibration of the entire drive unit is fully automatic. High-precision, detailed analysis, easy to operate and an exceptional price all make the ConturoMatic CV systems very attractive.

For more complex requirements:

With a measuring area of 70 x 250 mm, the completely digital CV500digital offers the largest measuring area in its class.

Still using a contour measuring device with outdated technology?

Regardless of the manufacturer, we can offer our ConturoMatic CV250 Retrofit as a retrofitting system. All existing and useful components such as the X/Y adjustment table, slab and vice can still be used. We will supply the necessary components in order to adapt our CV250 and you will benefit from a cutting-edge measuring device that corresponds to the state of the art.

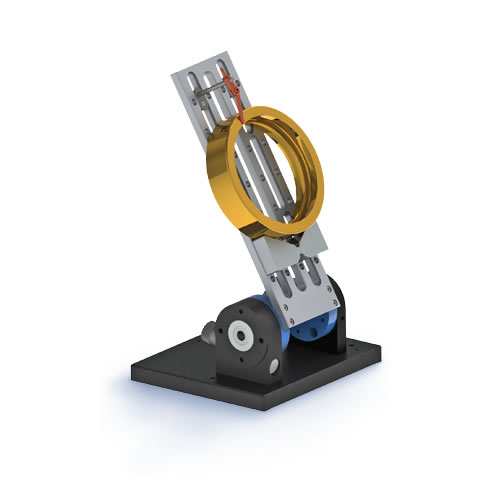

- Stationary, profile-method contour measuring device

- Stationary, profile-method contour measuring device

- ConturoMatic software: W7/64 bit

- External operation via standard PC interfaces

- CV250 measuring area: 50 x 250 mm

- Positioning of the Z-column: 400 mm (or, optionally: 600 mm)

- Software-controlled probe arm lifting

- Automatic measurement using teach-in programming

- Can measure even extremely large and heavy objects

- Movement on all axes can be automated

- Easy to replace the probe arm

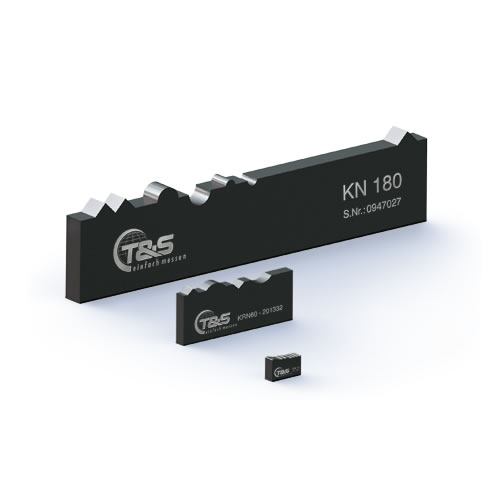

- Calibration standard for dynamic X/Z calibration included in delivery

- Stationary, profile-method contour measuring device

- Stationary, profile-method contour measuring device

- ConturoMatic software: W7/64 bit

- External operation via standard PC interfaces

- CV250 measuring area: 70 x 250 mm

- Positioning of the Z-column: 400 mm (or, optionally: 600 mm)

- Software-controlled probe arm lifting

- Automatic measurement using teach-in programming

- Can measure even extremely large and heavy objects

- Movement on all axes can be automated

- Easy to replace the probe arm

- Calibration standard for dynamic X/Z calibration included in delivery

Retrofitting system for older systems from various manufacturers

The slab, cross table and workpiece mount of the existing system can all still be used. We will provide an adapter plate and all necessary components. After assembling the units provided, you will once again have at your disposal a fully updated contour measuring system.

Included in delivery

- CV250 drive unit

- External measurement and control unit

- W7/64-bit evaluation computer, printer, set of cables, 19“ TFT

- Motorised Z-column

- ConturoMatic evaluation software

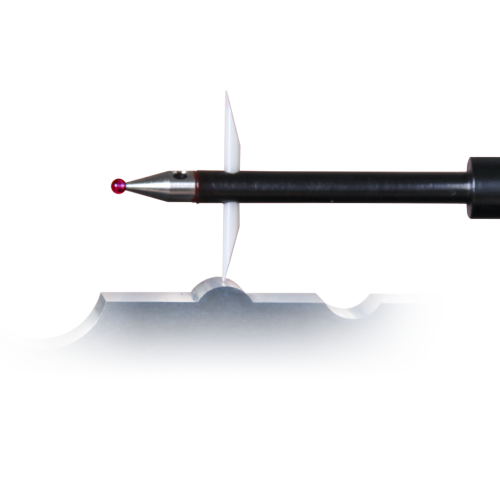

- Standard probe arm 260/33 (25 μm ceramic)

- Calibration standard – Industry joystick

- Instruction manual

- Adapter plate for mounting the CV250 column on the existing Mahr hard stone plate