Contour and roughness measurements

at the highest level

Our proven concept motivates us to continue developing our systems.

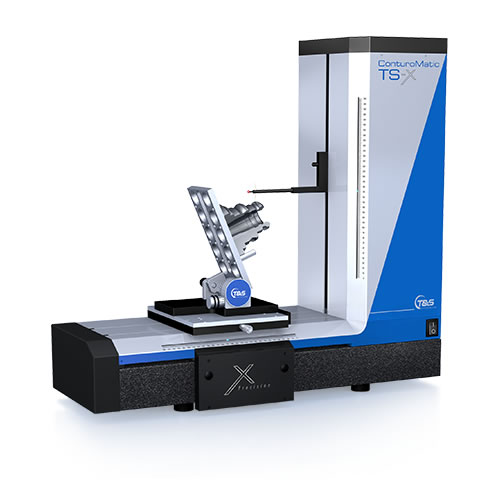

In line with the motto “The best is not good enough”, we have once again carefully scrutinised every single element concerned with system precision in the ConturoMatic TS.

Meticulous fine-tuning of the guides, aerostatic air bearings, high-speed data transfer, fast-reaction axis tracing, optimised tracing arm bearing, newly developed drive units and incremental scales of the highest quality are the results of a comprehensive and constantly evolving development process.

This process has given rise to the latest achievement from T&S – the ConturoMatic TS-X – our most efficient measuring station.

Leistungsmerkmale der TS-X im Überblick

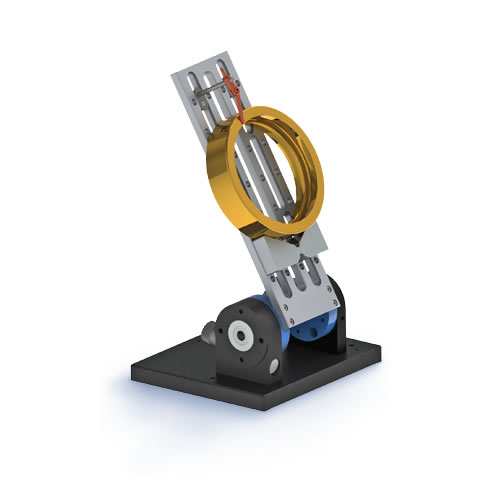

- Software-controlled, motorised adjustable Y-table for automatic zenith search.

- Special frictionless aerostatic air bearings for the X and Z-axes

- Enlarged measuring range (280 x 350 mm)

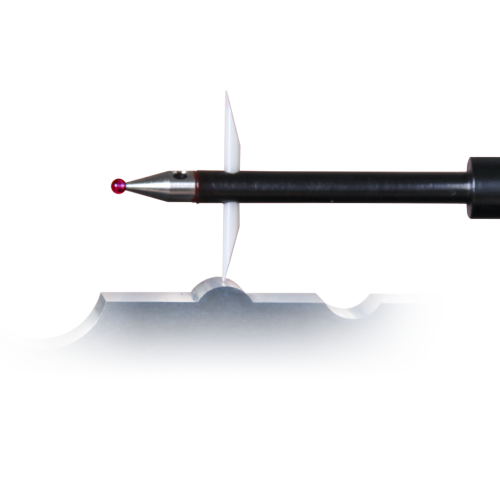

- Tracing arm bearing in hybrid ceramic

- Static scanning and recording of measurement data along the X-axis

- Roughness analysis module in the standard scope of delivery

- Table load of up to 25 kg (optionally 50 kg)

- Non-contact incremental linear scales on steel base

- Measuring system resolution of 0.1 nm

- Outstanding value for money

- Accuracy: ± (0.85 + L/100) µm [L = measurement displacement in mm] (no change in measuring direction)

- Combined contour and roughness measurements possible over the entire measuring range

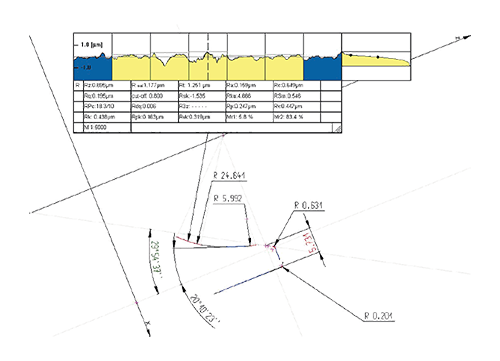

Contour and roughness in a single step

State-of-the-art contour measuring systems increasingly permit data acquisition and calculation of roughness parameters too. Roughness measuring of steeply inclined contours brings an ever-increasing number of previous scanning procedures and assessment methods to their limits.

To solve this problem, our calculation algorithms have been based on orthogonal regression from the outset. This method, in connection with dynamic speed control, which ensures even data point distance, leads to perfectly precise results – even on heavily tilted surfaces. In contrast, conventional solutions for achieving constant measuring point distances require the generation of theoretical points, which haven’t actually been measured, via interpolation.

The necessary components for measuring roughness are already included in the standard package delivered with the ConturoMatic TS-X. In addition to contour measuring, your contour measuring station also offers a high-performance system for measuring surface characteristics. All common parameters can be automatically measured and evaluated. The software is seamlessly integrated into the standard software and can be operated intuitively.

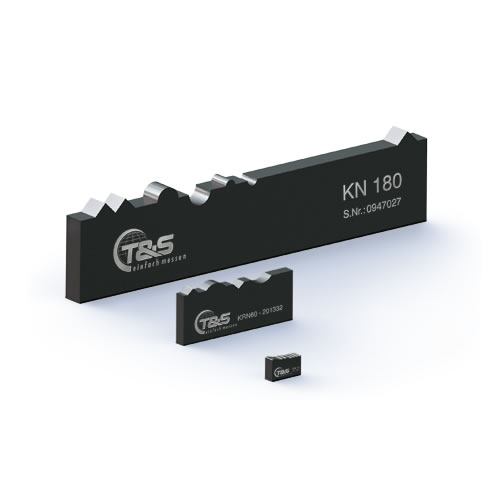

- Measurement of surface roughness possible by physically measuring a reference model.

- Measuring range of roughness: 280 x 350 mm

- Effective resolution: 0.1 nm

- Measuring speed: 0.1–0.5 mm/s

- Measuring force: 7.5 mN

- Measuring point distance: approx. 0.5 µm

- Suitable for roughnesses: Rz > 0.5 µm, Ra > 0.05 µm

- Accuracy: 5%

- Pt, Pz, Pa, Pc, Pq, Pp, Pv, Psk, Pku, PSm, Pdq, Pmr(c)

- Rt, Rz, Rzi, Rz1max, Ra, Rc, Rq, Rp, Rv, Rsk, Rku, RSm, Rdq, Rmr(c), Rk, Rpk, Rvk, Mr1, Mr2, Rmax, R3z, RPc

- Wt, Wz, Wa, Wc, Wq, Wp, Wv, Wsk, Wku, WSm, Wdq, Wmr(c)

- Dominant waviness WDSm, WDc, WDt according to VDA 2007:2007-02 (optional)

- Filtering by phase-correct Gaussian filters

- Robust Gaussian filter in accordance with ISO/TS 16610-31:2010 (optional)