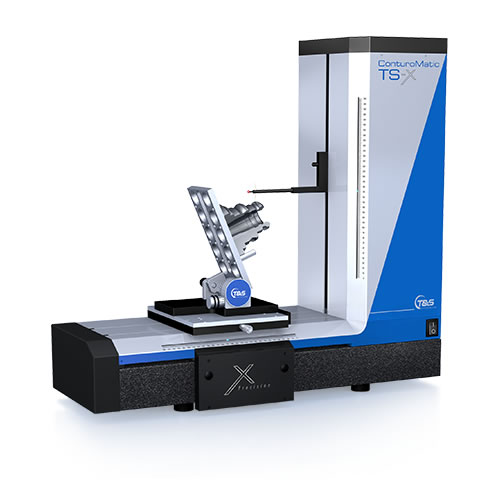

Simple and fast contour measurements

The user’s requirements have always been our top priority. Ensuring contour measurements can be made simply and fast has been our guiding principle from the very outset. The art to this is combining the simple and intuitive operation of systems with unlimited versatility.

Our solution: ConturoMatic S1 analysis software.

The operating concept of the ConturoMatic S1 analysis software is perfectly suited to both production monitoring and use in a measurement lab. Basically, any contour and roughness measuring instrument draws on the profile method. It was with this in mind that we developed a uniform software base to act as an interface with the user.

Increased efficiency thanks to ongoing development

We foster the close communication we have with our users. It enables us to quickly and purposefully integrate customer suggestions into the ongoing optimisation process for our software solutions.

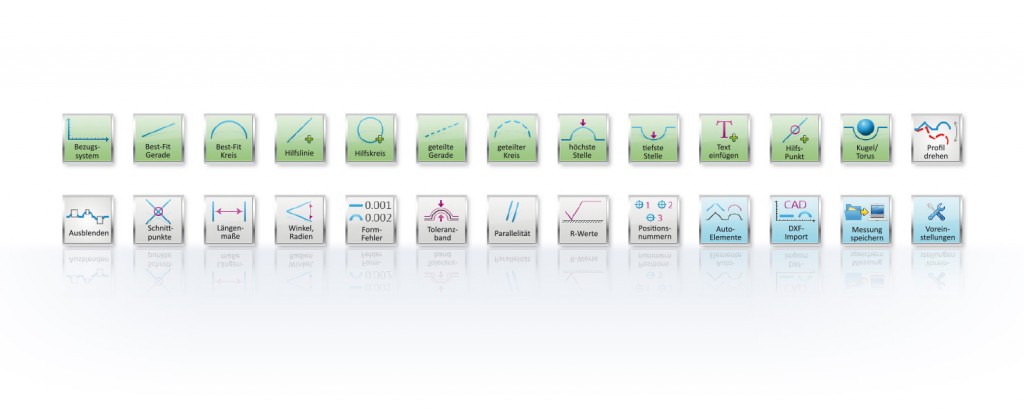

Benefits at a glance – measuring made easy

- Every analysis feature can be accessed at the click of a mouse – no complicated menu items or sub-features

- Evaluations and tolerance comparisons that are independent of user and thus protected from operating errors can be made fully automatically during production monitoring

- Basically, any completed measurement comprises everything required to generate an automatic test sequence, including analysis. Teach-in in its purest form

- Three basic steps lead to an automated test: measure, analyse, save

Measuring with more precision:

- Parts that were previously hard to measure can now be dimensioned in a clear and reproducible manner

- The software is largely geometrically tolerant

Equipped for the future:

- Our ConturoMatic software forms the basis of our TS and CV systems and undergoes ongoing development

- Software updates and extensions are available to our customers free of charge

- Calibrate base frame

- Regression curve, single or multiple variables

- Regression circle, single or multiple variables

- Specifying start and finish angle for regression circle

- Specifying start and finish angle for regression curve

- Calculation of radius, distance, angle, incline, etc.

- Angle displayed as °/’/”, decimal, inclines in μ/mm

- Creation of auxiliary elements, circle, line, point, system of coordinates, parallels, vertical

- axes, angle bisectors, angle lines, etc.

- Fixed circle fitting

- Creation of line/line intersections

- Creation of auxiliary line/contour intersections

- Creation of line/radius intersections

- Creation of free reference points

- Calculate highest point

- Calculate lowest point

- Creation of variable vanishing point in mm or %

- Fitting a line through x points

- Fitting a circle using x points

- Rotating ball mapping

- Torus mapping

- Deviation from linear form, graphically scalable on X+Z axes

- Deviation from radial form, graphically scalable on X+Z axes

- Calculation of parallelism

- Rotate profile

- Hide segments

- Automatic dimensioning with tolerance evaluation

- Integration of graphic as information for automatic test sequence

- Red/yellow/green digital tolerance indicator

- DXF mapping

- Free-text comment field

- Contour-specific comment field

- Surface roughness measurement (optional for T1, standard for T3)Large print processor

- Automatic assignment of print templates to reference element measurements

- Automatic print-out after reference element measurementResult as a list with tolerance evaluation

- Print-outs in portrait or landscape format

- Position numbering system

- Dynamic contour tracking

- Importing various exchange formats and data from external systems

- Flexible data export

- Automatic data export after reference element measurementsExport results

- Export raw data

- Export DXF data

- Easy to create autonomous test sequences

- Intelligent optimisation of travel distance

- Option to display grid lines

- Dynamic axis scaling

- Customisable display colours

- User-led scan arm calibration

- Choose from 12 user languages

- User management

- Compatible with Windows XP and W7 (32/64 bit)

Measuring instruments and software from a single source